Discussion

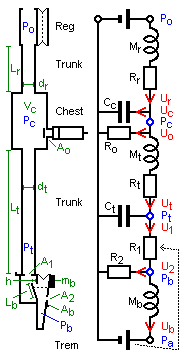

In an existing installation most parameters like trunk and

trem bellows dimensions are already given. Then you can

examine what happens when changing the parameters A1, A2, and mb supposed

to be the normal parameters for an adjustment.

The net airflow consumption of the trem is U1 which has

a waveform typically reminding of half sinusoids, skewed to

the right. This excitation shape is typical for many airflow

interrupting devices like reed pipes, diaphones, orchestral

reed and brass instuments, and the human glottis. Indeed the

whole trem system can be likened to a diaphone pipe, blown

backwards from its mouth at the supply regulator. Like in

the mentioned examples the pulse flow from the interrupter

is connected to a resonator, in our case the trunks and the

chest, to produce an amplified flow oscillation Ur at the

mouth, and which may reach quite high values. It should be

noted that part of a trem cycle this flow may go backwards

to refill the regulator. The regulator is supposed to

deliver a constant pressure Po. Even when it manages to do

so, its bellows lid will oscillate because of the

alternating Ur.

Example calculation: With Ur about

sinusoidal 100 lit/sec peak/peak at 7 Hz, then the volume

displacement in the regulator will be U/(2π *f) = 100/(2π*7) = 2.3 lit p/p.

That renders a lid oscillation about 6 mm p/p when the lid

area is 0.38 m2.

The regulator in this simulation is assumed to be perfect in

delivering a constant driving pressure. A practical one may

vary somewhat in static

output with its reservoir fill, depending on how its bellows

and spring/weight load match. This is a problem that has

minor influence, not accounted for here. A decently

constructed regulator usually holds its static pressure

within few percent. The initial version of this essay has

received some criticism because of this assumption that

consequently excluded the regulator from the simulated

network. The reason to exclude it is that otherwise the

total number of parameters would tend to be too high to

handle. The assumption is generally good as long as the

pulsating flow Ur

is not big enough to make the bellows bottom out.

However, after finding a working parameter set for the trem

and you know Ur,

then it is wise to run the accompanying regulator simulation

program to check how it can handle that flow.

A different thing is the important one, namely the inertia of the

regulator. This is its acoustical mass which is found from

bellows lid area and weight, including ballast if any.

Knowing these data you can account for its effect by adding

it to Mr

by an increase in the trunk length Lr.

Example calculation: With a

regulator lid weight m

= 15 kg, area A

= 0.38 m2, its acoustical mass is M = m/A2 =

15/0.382 = 104 Ns2/m5,

about one third of Mr

in fig 5. You can account for that by elongating the trunk

about 0.6 m.

It is important to understand this equivalence between

regulator lid weight vs. regulator to chest trunk length.

Both have the same effect to swamp regulator action what

regards changes in

airflow, but little concerning static conditions. This is

further elaborated below in the technical section about

trunks.

Following the lid, the regulator input valve will oscillate.

This will partly invalidate the reasoning above, since

regulator flow is not only its lid displacement flow, but

also refilling flow pulses. However this generally has a

relatively minor influence on regulator output, even when

its upstream pressure varies considerably.

The pressure Pt

at the trem input varies much more than the chest pressure.

There is a sharp pressure rise when the pallet closes, the

hydraulic hammer effect, an expedient to keep reliable

oscillation. It is noteworthy that the diameter dt of the

chest to trem trunk is of some importance here. If you make

it too large, then the linear air speed corresponding to Ut will be

small, reducing the hammer effect.

The trem input slider A1

limits the exciting U1

pulses and often appears useless, having little effect until

you make it rather small. It is sometimes left wide open to

allow for maximum pipe load which is controlled by Ao. If used

the trem function may deteriorate unless A2 is fine

adjusted.

|