Tracker project

A

developing progress report on a venture where the outcome is

rather uncertain. Any comments, suggestions, encouragements, or

discouragements are welcome.

Version 1: 05-06-15, 2: 05-06-25, 3: 05-07-22

Johan Liljencrants

|

For

some

time I have pursued a reactionary project to supplement my

organ MIDI control with a punched paper tape reader. Apart from being

old fashioned there are a number of problematic issues with this, like

making the tapes, feed them reliably over the tracker, and keep

hygroscopic size variation under control. The main positive feature is

that of its visual impact, the solid demonstration of how the organ is

controlled. Also, in my yet limited experience, the presently weakest

link in the system is indeed connected to the electronics system, like

diskette read errors causing abrupt music halts, or inconveniently

complicated multiple control button pressing.

The following covers some key issues of this project, some of

which are almost solved, others still in a planning stage.

Paper tapes

Conventional self playing organs use

either pneumatically read paper

tape rolls, or fanfold cardboard books sensed by mechanical means. The

aim in this project is to combine positive features of each, namely to

use fanfold paper tapes, inspired by the DEC computer tapes of the

1960s. These paper books will then be very compact to store and there

is no call for return spooling. These are to be read pneumatically, but

a main foreseeable problem is how to avoid misreadings at the paper

folds.

The current specification sets out from practical reasons like tape

width 297 mm (long side of A4 paper format) and 200 mm fold divisions.

104 channels on 2.5 mm divisions will occupy 260 mm of punched width.

This number of channels suffices for my organ except its percussive

harp. Possibly the harp can be accommodated using an additional

register

control, not yet implemented. The divisions measure is motivated by my

metric tools for

tracker bar and punch fabrication. This format will not coincide with

any one presently known, but it is anticipated that music arrangements

will

anyway be unique to this organ. Until an automated punch device is

developed I believe computer MIDI printouts will give templates that

are easy enough to use for guiding a manual punch.

Transport machinery

Because of available space this

reader is unusually short in the paper

travel direction, about 280 mm over all. This makes it relatively

difficult to control the paper sideways position, calling for active

devices.

In the drawing below the tape is driven from a payoff bin at left, over

the

tracker bar surrounded by two curved guide plates, into a takeup bin at

right. The tape is driven by a rubber capstan extending

some 2 mm through a hole in the right guide plate. On top is a bridge,

pivoting around its left shaft which also carries a gentle leaf spring

to press the tape against the tracker bar. The bridge right shaft

carries the 'pinch roller' pressing the tape against the capstan. This

is a tube extending the whole width of the tape and is held by ball

bearings at its ends.

This

photo is a general overview of the assembled unit, mounted with ball

sliders on two support rails. This allows the unit to be pulled out

from its storage position in the organ cabinet for easy access. The

bins and these rails are keyhole mounted such that they are easily

unhooked. The pinch roller axle holds eccentric segments at its ends,

resting against the capstan support plate. This axle can be rotated

somewhat with a small spoke in order to engage or disengage the pinch

roller.

The width of the payoff bin is

just some 1 mm more than the tape

width and is supposed to guide the tape sideways initially. The takeup

bin is some 5 mm wider. It is important that the wide paper tape is

fairly closely guided near

the

tracker bar, otherwise it easily wrinkles as it alternately folds

up and down. On the entry side this is done by the guide leaf

spring, on the exit side by the pinch roller being a long tube rather

than just short rollers.

The outside curvature of the bins appears essential to make the paper

unfold and fold graciously.

The tracker bar is made from 20 mm hexagonal alloyed alumin. Its

sensing holes

are 1.8 mm diameter at 2.5 mm divisions, drilled to the center of the

bar. On the back two oblique sides there are continuation holes to

connect to the

switches. These alternately go to the leading and trailing sides of the

bar, such that the connection holes come at 5 mm divisions. The

coupling to the two switch rails is with short flexible PVC

tubes.

After drilling the holes the bar was excentrically put in the lathe and

the sensing surface was turned into about 15 mm radius.

|

The

ends of the tracker bar are supported by vertical leaf springs such

that the bar is easily mobile in its axial direction. Two extreme holes

in the tracker bar sense the edges of the paper tape. These holes vent

two balancing bellows that are evacuated via bleeds to the suction

source. This bellows array is geared with an arm to the tracker bar in

order to

align the bar with the actual sideways position of the tape. In the

present

design the bar can move over a range of 3 track divisions in about 2

seconds time. The rocking armature hinges on two central pins and is

held in place by a strong crosswise leaf spring, pivoting on brackets.

This is a toggle pressing the rocker toward its end positions, a

partial compensation for the elasticity of the bellows cloth and the

bar suspension. |

| It is easy

to take out the various subassemblies like the drive motor

gear, the alignment bellows, the curved guide plates, and the bins.

Each is fastened to the wooden main frame with two machine screws. Once

these units are taken away the tracker bar and the switch rails can be

lifted out together. |

|

The sideways control of the

tracker bar seems to operate well. Still, when the

tracker bar is found to go

toward one side, then the drive mechanism should make the paper tape

wander back toward its correct path. Initially I tried two capstans,

one each side of the

tape, hoping that direction might be controlled using the pinch roller

pressure. In my practical

experience

this does not work. The double capstan was then abandoned in

favor of a single one at the paper

center line.

The key feature is that the feed direction of that

capstan can be controlled to be slightly off axis, in my present

experiment up to +/-3 degrees. When the tracker bar is

sideways adjusted by the sensor holes and bellows, that same excursion

is used to yaw the feed direction of the capstan. After some effort at

the

drawing board I arrived at the following design which indeed appears to

work in the same time as it reasonably simple to make.

|

The motor

driven capstan shaft (right of capstan in this drawing)

is

rigidly supported by ball bearings at

both its ends (motor end not shown). The shaft capstan end is

approximately ball shaped, resting in a bushing at the center of the

capstan. A hole is drilled through this bushing and the shaft and a

small pin is inserted. With adequate backlash this implements a half

cardan joint. A spoke extends from the other (left) end of the bushing.

The far left end of this rotating 'yaw' spoke rests in a link arm that

connects its direction to the tracker bar sideways position. |

This drawing shows the under side

of the trailing guide plate

which carries the capstan and its control, and also the tracker bar.

The red markings show how the capstan is yawed when the tracker bar is

displaced leftward by the edge sensors and bellows.

Reading switches

These switches are

suction-to-electric converters. They can be

connected in parallel to the present MIDI decoder and serve as an

alternate control option. The design is a

variation on the recipe by Richard Vance at

http://www.mmdigest.com/Tech/vanceSwitch1.html.

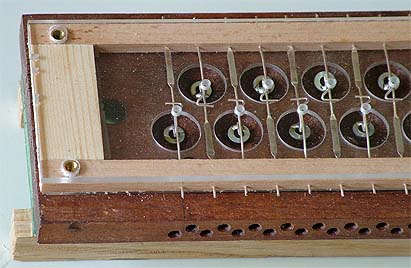

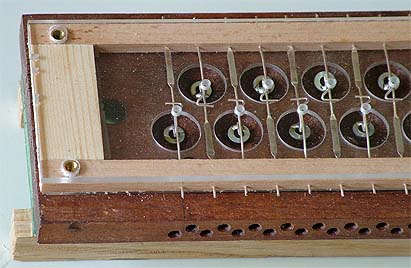

Initally I tried a small 8 channel prototype in a plexiglass body, 2.5

mm divisions and 8 mm cavities. Dismissed that as too difficult to make

and adjust. Then made a short 4 channel copy with 5 mm divisions and 15

mm cavities like shown below, which seems to work OK. Major parts for

the complete system are built, but fabrication of contacts withheld

until transport design is finalized.

| To

accommodate the totally 104 switches within managable space requires

multilevel staggering, the first one is to split from the tracker bar

into the two rails. Next level is to alternate between front and back

sides of a rail (black and red in the sketch), and finally

between an upper and a lower row. The general layout is maybe seen

in this sketch of the end of one of the rails. |

|

The central part is a 12*80*330 mm

mahogany piece with 2*2*13

pouch cavities, 15 mm diameter. On each side, over these cavities

is a 1.5 mm plexiglass plate with a glued-on wooden frame to carry the

contact wires. These plates are drilled in the same operation as that

for the underlying cavities. The pouches are formed by a coherent sheet

of pouch leather (red below), compressed without glue between the 1.5

mm sheet

and the wooden base. Outside this are 3 mm plexiglass plates carrying

contact adjustment screws in threaded holes, and finally wooden bars to

hold the complete assembly together. The inner sides of these bars are

made slightly convex in order to distribute their compression force

more evenly along the rail - there is little room for compression

screws except at the ends of the rails.

|

This drawing shows more detail

on one single switch, for clarity

neglecting its neighbors.

The photo is from before adjustment screws and pouch leather are

installed.

|

|

The internal volume where the contact

springs are located is connected

to the suction source. For each cavity there is a 0.8 mm bleed hole

drilled through the 1.5 mm plexiglass, leading to the channel toward

the tracker bar. It is a fairly exacting operation to perforate and

mount the pouch leather sheet to match with these bleed holes.

The contacts are made from 0.8 mm sterling silver wire. Each contact is

two parts, one 'fixed' albeit adjustable with a screw, and one moving

with its end actuated by the pouch. The stem of the moving contact is

flattened into a leaf spring, 0.25 mm thickness. This flattening is

done using a steel bar with thickness control shims added. The contact

wire is placed between that bar and an anvil and the bar is hit with a

sledge hammer. Hammering is repeated until a micrometer or caliper

tells the correct thickness has been reached. The end of the moving

contact is bent and tin soldered to a small washer that rests on the

middle of its pouch.

After preliminary shape adjustment the contact wires are locked in

place in their mounting holes with cyanoacrylate glue.

When the tracker hole is covered, then the whole unit is under the same

suction, the contact spring presses the pouch into its cavity and the

contact is open. With an open tracker hole only the contact cavity is

under suction and the pouch lifts the contact spring until it makes to

its fixed counterpart.

For

some

time I have pursued a reactionary project to supplement my

organ MIDI control with a punched paper tape reader. Apart from being

old fashioned there are a number of problematic issues with this, like

making the tapes, feed them reliably over the tracker, and keep

hygroscopic size variation under control. The main positive feature is

that of its visual impact, the solid demonstration of how the organ is

controlled. Also, in my yet limited experience, the presently weakest

link in the system is indeed connected to the electronics system, like

diskette read errors causing abrupt music halts, or inconveniently

complicated multiple control button pressing.

For

some

time I have pursued a reactionary project to supplement my

organ MIDI control with a punched paper tape reader. Apart from being

old fashioned there are a number of problematic issues with this, like

making the tapes, feed them reliably over the tracker, and keep

hygroscopic size variation under control. The main positive feature is

that of its visual impact, the solid demonstration of how the organ is

controlled. Also, in my yet limited experience, the presently weakest

link in the system is indeed connected to the electronics system, like

diskette read errors causing abrupt music halts, or inconveniently

complicated multiple control button pressing.