Pipes

The organ has a total of 247 pipes.

Mostly

in wood, but 25 counter melody clarinets are in brass. In the table

below the

MIDI

columns 'Reg' and 'Note' is the respective note numbers used for

control.

'Sound' refers to what pitch is actually produced by the pipes. The

counter

melody pipes sound 4 octaves higher than their control codes, they are

-48

semitone steps transposed in the MIDI score. The chimes note controls

are transposed +29

steps.

| Chest |

MIDI |

L/W(69) |

Pipe

type |

| Reg. |

Note |

Sound |

| 8 *

Bass

(G A #A B C D E F)

|

0 |

43-54 |

43-54 |

12

|

open

flue, detuners

|

| 1 |

31-41 |

12

|

cyl. reed |

| 12 *

Accompaniment

(G .. F+)

|

2 |

55-66 |

55-66 |

24

|

open flue cello

|

| 3 |

55-66 |

12

|

open flue |

| 4 |

43-54 |

12

|

cyl. reed |

| 25 * Counter

melody

(C .. C)

|

5 |

12-36 |

60-84 |

12

|

open flue |

| 6 |

72-96 |

24

|

open flue

violin |

| 7 |

60-84 |

17

|

reed

clarinets |

| 30 *

Melody

(G .. C)

|

8 |

67-96 |

55-84 |

12

|

stoppered

flue |

| 9 |

67-96 |

9

|

flared trumpet |

| 10 |

67-96

|

12

|

open

flue |

| 11 |

67-96 |

24

|

open flue violin |

| 20 * Chimes

(C-G) |

- |

101-120 |

72-91 |

|

tuning forks w. resonators |

| Tremulant on |

39 |

|

|

|

|

| Reg. cancel |

40 |

|

|

|

|

Bass chest

Reg 0: Open flue pipes

|

|

An initial

set of stoppered basses turned out a

little too meek.

Having

now

finalized the height of the cabinet to be more than planned when I

first

made those pipes long ago, I made a new set, this time

open pipes with the same diameters (51..71 mm, 2..3 in). Only the two

lowest

ones, for G (1.75 m long) and A had to be mitered.

The body of them is made from 7 mm pine

plywood except the front

that

is oak. In respect of their size I made good use of a table saw and a

shoulder

plane to make the long joints with grooves and tongues. Some extra work

that pays off when it comes to gluing. First back and sides, with the

front

loosely in place to keep the sides parallel. Next round, after fine

trimming

the two bottom blocks are glued and, having clamped those, the front. |

| The mouth

design like shown, gives a

fairly large degree of freedom

in voicing. A number of loose pieces, in particular a little bar f,

resting in notches in the ears e, to hold down the adjustable

upper

lip a with an elastic leather gasket in between. Nothing is

glued

here, all is held together by the slim screws through the ears into the

sides of the body, plus a crosswise threaded bolt with nuts through the

intonation roll d. The roll has a big hole in it to allow for

fine

adjustment of its position. So far I have always found the lowest point

of the roll should be on the plane of the languid, the adjustment to be

done is the distance to the flue jet. Perhaps the least elegant

adjustment

is for how the jet hits the labium - can be modified with shims between

a

and b unless you do some carving in b or remake a.

The round hole in it is a pull-out handle, decoration, and trigger for

people to ask what for. |

|

|

These pipes have tuning sliders

at their top end, somewhat

more

elaborate than with the smaller pipes. They are made from brass sheet.

Inside the pipe, each side of the tuning slot, is an oak stick with a

threaded hole, held by a locking screw. Tightening these screws presses

the

slider firmly against the inside of the pipe front.

Four of these eight pipes are equipped with detuners, such that the rank implements a fully

chromatic octave.

|

|

Reg 1: Bass reed pipes

|

These are

the lowest bass pipes,

cylindrical 'bass clarinets', one quarter

wavelength. Also this rank replaces an initial one, namely conical

trombones. These clarinets are somewhat

longer

than the trombones, but they speak one octave lower. Since the boot has

a rather small volume it is fitted with a spring loaded diaphragm to

make

a 'schwimmer'. This acts to reduce the AC pressure variations inside

the

boot

and is good to ease voicing and to stabilize reed oscillation.

The boots of these pipes have little flags, strips of motor cloth,

fixed with screws at the top ends, and marked with white dots at the

low free ends. Behind each flag is a small hole such that when the pipe

is blown the flag swings out to visualize that the pipe is on.

|

|

|

|

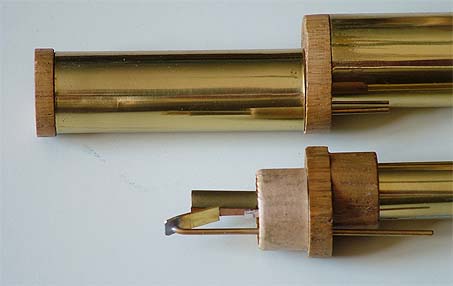

The shallots are made from copper

pipe, slotted and with

a

brass

cover plate soldered on. This plate has a hole extending under part of

the tongue and is covered with glued on pouch leather. The tongues are

brass,1.2 to 1.5 mm thick, held by a

pair of

screws threaded into the shallot plate.

|

Accompaniment chest

Reg 2: Accompaniment cello pipes

This is a set of

narrow

violin-type pipes that are a continuation downward from the melody

violins. The design is shown at the section of the countermelody

violins, register 6.

This is a set of

narrow

violin-type pipes that are a continuation downward from the melody

violins. The design is shown at the section of the countermelody

violins, register 6.

Reg 3: Accompaniment principals

|

These pipes form a link between

the bass (reg 0) and melody (reg 10) flutes having the same scale.

Bridges have been added later to allow for wider flues and more power

without overblowing. On the chest this rank is placed between the

cellos (reg 2) and the reeds (reg 4) such that nobody can see those

ugly bridges.

|

Reg 4: Accompaniment reed pipes

|

The

resonators of these are a continuation upward of the bass reed pipes,

speaking one octave below the other ranks on the accompaniment chest.

The shallots and boots are inherited from an earlier, but discarded

rank of conical pipes.

The resonator front plate is bent slightly inwards in the lowest part,

in order to give room for the tuning wire.

The jack mechanism to adjust the tuning wires with a screwdriver is no

good invention. It is rather easier to tune them the conventional way

knocking the wires.

|

Counter melody chest

Reg 5: Counter melody flutes

|

Made from

oak slabs, recovered

from an old parquet floor.

They are deeper than wide by a ratio of 4:3. This is the only rank

(except the trumpets) where the cross section deviates from square.

Bridges cover the entire mouth area. These features allows the airband

to be quite thick without overblowing, so these pipes are

comparatively loud. |

Reg 6: Counter melody violin pipes

This rank is made identically like the melody violins, register 11.

|

These very skinny pipes are

made from recycled old fir. The resonators of the dozen smallest pipes

are formed as a milled grooves in integral back pieces, covered by

front plates, chamfered for the labium. The bigger pipes are assembled

conventionally from four plates plus a bottom block.

The cut up is fairly low and they are vigorously blown. To prevent

overblowing the height of the bridges was carefully adjusted in the

same time as the flue width was made as large as possible.

The

inner surface of the bridges is intuitively streamline shaped. The

chamfering of the covers is essential to let air be entrained with the

jet. The sound from these pipes is amazingly loud and penetrating,

regarding the minute size of the openings in the mouth region. |

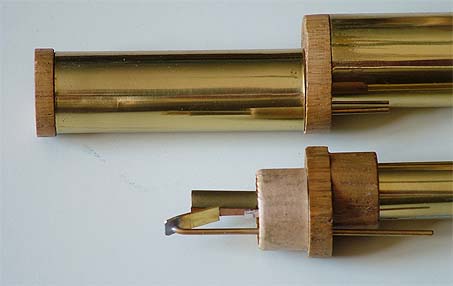

Reg 7: Counter melody reed clarinets

|

The

central

head piece, made from oak, has upper and lower cylindrical surfaces

with

offset

axes. This offset gives room for the tuning wire running parallel to

the

tubes. The resonator tube and the boot are both

plainly

cylindrical. Nominal 1/4 wavelengths are quite close to

the

actual lengths of the resonator tubes. Diameters range from 29 to 17

mm,

halving number about 24.

The

tubes are made from standard half hard 0.2 mm brass sheet. This is much

springier

than pipe tin alloy, makes it difficult to shape them, but has a good

tensile

strength such that I can have such a thin wall and save a lot of

weight.

The tools to shape them was a set of cylindrical oak dowels, diameters

29,

25, 22, 19, 17, 15, 13 mm. I used only these

listed

diameters, about 5 pipes each size, no need to make individually

interpolated

diameters. |

Melody chest

Reg 8: Melody stoppered pipes

|

This rank

was built with the same basic design and measures as the open flutes

below (reg 10). Because they are stoppered they however speak one

octave lower, and this calls for a higher cut up, other parameters

constant.

|

Reg 9: Melody reed trumpets

| MIDI |

Note |

Freq |

Wavel |

Lh

mm |

Wm

mm |

| 69 |

a' |

440 |

780 |

273 |

39,0

|

For the other pipes lengths are

proportional to the inverse of frequency, and diameters to the square

root of that.

|

For the

shape of these resonators I arbitrarily decided on the area function A=Ao*exp(3*x2),

where Ao is the

throat area and x is the relative length coordinate along

the horn, from 0 to 1. This is not a common exponential horn because

the x

argument is squared. This means the flare is moderate in the throat and

much more drastic toward the mouth, an expedient to make it a little

more trumpet-like. There is a factor 3 for the argument,

meaning that the mouth area will be exp(3)=20 times larger than the

throat area. On top of this I prescribed that both the throat and the

mouth are to be squares. Mouth diameter is then about sqrt(20)=4.5

times throat diameter.

This defines the relative shape of the resonators. After making a

prototype I found the length of the resonators should be 0.35

wavelength. Skinniness was arbitrarily selected to L/W(69)=10

(half wavelength/mouth diameter for reference note a') and the halving

number M=24. This results in

horn length Lh

and mouth diameter Wm

for the a' pipe as shown beside. |

Two opposing sides of the horn are straight edge trapezoids, bent into

shape. The other two are flat but with edges that are intricately

curved to make up the desired area function. All sides are made from 4

mm birch plywood, made from three layers of veneer. The pieces were

oriented such that the middle layer grain goes along the pipe, the

visible layers across. Unless you orient them that way you cannot bend

the trapezoidal sides without breaking them.

| To make the

curved side pieces I started from this drawing (blue contours), as

computed

from the formula above, respecting contribution from the trapezoidal

shape of the companion sides (red contours). The cross section of the

horn at half its

length is a quite oblong rectangle. Next step was to make copies of the

drawing, one for each pipe, appropriately scaled lengthwise and cross

wise. These were glued to the plywood stock, laid in two layers, and

served as templates for cutting out the blanks. |

|

The trapezoidal pieces were made with

extra width to account for the thickness of the side pieces plus a

margin for trimming. Then made shoulders on their long sides with a

shoulder plane, such that the remains met the required internal width

measures. I took away only the innermost veneer and its glue layer,

about 1.3 mm. The curved pieces were accurately trimmed. Width plus

twice the

shoulder depth was checked with a caliper against a big table produced

with an Excel sheet. Pieces were always held pairwise together in a

vise.

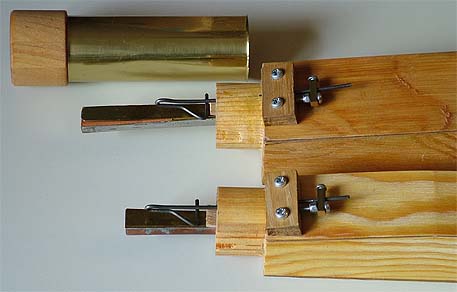

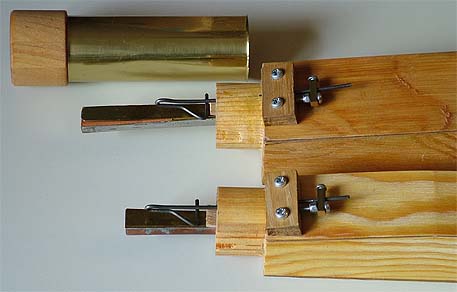

The

horns were glued with plain white glue to give enough time to

adjust the pieces accurately while clamping. The positioning and

clamping of the four horn pieces is critical. I found the special jig

visible beside to be indispensable for the task. It is two square

angles that are adjustably held together by screws with wing nuts.

Before the gluing operation they are set to contain a rectangle

matching the horn about 1/12 of its length from the mouth. When glue

has been applied to the shoulders of the trapezoidal pieces you

assemble the four pieces in your hand, let on the squares jig, and

clamp the throat temporarily. Then you have to press the jig firmly in

direction toward the mouth. Once the jig is in place you can clamp the

rest of the

horn easily, observing to push the side pieces all the way onto the

shoulders.

After trimming the outside a number of oak pieces were glued outside

the throat, which was also plugged to a depth of 20 mm to later accept

a hole for the shallot. The head was then shaped in the lathe.

Reg 10: Melody flutes

These are made from oak slabs

recycled from a parquet floor. It is the first complete rank I built

for this organ after exporing the subject of flue dimensioning. The

design follows my original MMD article

Recipe

for

Wooden Organ Flue Pipes which includes dimensioning formulas

and their implementation in an Excel spreadsheet. The same design

and basic dimensions was used for the stoppered pipes, reg 8.

|

Except the

highest pipes most are equipped with intonation rollers between the

ears to prevent overblowing. The precise position of a roller has to be

tried out during voicing operations.

After cutting a small recess in the cover, the inside of the cover and

the outside of the body are ground flat. One idea with this design was

that it might make it easy to control the flue slit by selecting and

perhaps grinding down the thickness of the gasket. Later experiences

tended to show it is easier to file down the languid, so that is what I

did for most of the other flue ranks.

|

Reg 11: Melody violin pipes

This rank is made identically like the countermelody violins, register

6, only it has five more pipes extending downward.

Surface finish

Brass sheet details are polished with a buffing wheel and paste. Then

coated with clear lacquer to avoid fingerprints which cause ugly

oxidizing marks.

After being glued together, but before voicing, all wooden pipes are

internally sealed off with

thin hot hide glue. Starting with the biggest pipe in a rank, tape over

its mouth and fill it with glue for some 20 seconds, then pour the glue

back into the pan. Remove the tape and let the pipe dry upside down on

a newspaper. This will close pores and small voids and leave a hard and

airtight interior surface.

Externally pipes as well as most carpentry is painted with boiled

linseed oil.

Dimensions table

For reference, here is an expanded

table, also linking the MIDI note

numbers n

(0<n<127) to the

conventional note names (A .. #G),

and the fundamental frequencies f

(pitches) of these notes in Hz. Only

the span covered in the organ is shown. The

underlying basis is the equally tempered scale and that standard pitch

is a'=440 Hz, MIDI note

number 69. The table thus shows the fundamental

frequency as defined by

the formula f = 440 * 2

(n-69)/12

The table also highlights the continuity of scaling across

the

different chests. For instance that the flutes of the bass,

accompaniment, and melody chests essentially form a coherent principal

rank.

|

The length dimensions stated are

nominal fractions of fundamental wavelength. Because of the end

correction the physical length of the tuned resonators are shorter than

this by about 2W for open pipes, by W for stoppered and reed pipes. The

total

pipe external length is greater, to include pipe foot/boot and material

adjacent to the top tuning device.

|

Note #1: Four of the bass flue

pipes have detuners to enable them to generate either of two adjacent

semitones.

|

Note #2: The melody chest

additionally holds a rank of stoppered pipes with the same key

dimensions as its open flute rank, but thus speaking one octave lower.

|

Note #3: The counter melody

flutes are 1.3 times deeper than the stated width W

|

Note #4: The counter melody

violins are identically the same design as the melody violins.

|

Note #5: The melody trumpets are

flared horns with a mouth area about 20 times larger

than the throat area. The stated width W is that of the square mouth

opening.

|

JLs

05-07-31

This is a set of

narrow

violin-type pipes that are a continuation downward from the melody

violins. The design is shown at the section of the countermelody

violins,

This is a set of

narrow

violin-type pipes that are a continuation downward from the melody

violins. The design is shown at the section of the countermelody

violins,

The

inner surface of the bridges is intuitively streamline shaped. The

chamfering of the covers is essential to let air be entrained with the

jet. The sound from these pipes is amazingly loud and penetrating,

regarding the minute size of the openings in the mouth region.

The

inner surface of the bridges is intuitively streamline shaped. The

chamfering of the covers is essential to let air be entrained with the

jet. The sound from these pipes is amazingly loud and penetrating,

regarding the minute size of the openings in the mouth region.

The

horns were glued with plain white glue to give enough time to

adjust the pieces accurately while clamping. The positioning and

clamping of the four horn pieces is critical. I found the special jig

visible beside to be indispensable for the task. It is two square

angles that are adjustably held together by screws with wing nuts.

Before the gluing operation they are set to contain a rectangle

matching the horn about 1/12 of its length from the mouth. When glue

has been applied to the shoulders of the trapezoidal pieces you

assemble the four pieces in your hand, let on the squares jig, and

clamp the throat temporarily. Then you have to press the jig firmly in

direction toward the mouth. Once the jig is in place you can clamp the

rest of the

horn easily, observing to push the side pieces all the way onto the

shoulders.

The

horns were glued with plain white glue to give enough time to

adjust the pieces accurately while clamping. The positioning and

clamping of the four horn pieces is critical. I found the special jig

visible beside to be indispensable for the task. It is two square

angles that are adjustably held together by screws with wing nuts.

Before the gluing operation they are set to contain a rectangle

matching the horn about 1/12 of its length from the mouth. When glue

has been applied to the shoulders of the trapezoidal pieces you

assemble the four pieces in your hand, let on the squares jig, and

clamp the throat temporarily. Then you have to press the jig firmly in

direction toward the mouth. Once the jig is in place you can clamp the

rest of the

horn easily, observing to push the side pieces all the way onto the

shoulders.