| Designation |

Species |

Color |

Density g/cm3 |

Hardness |

Provenience |

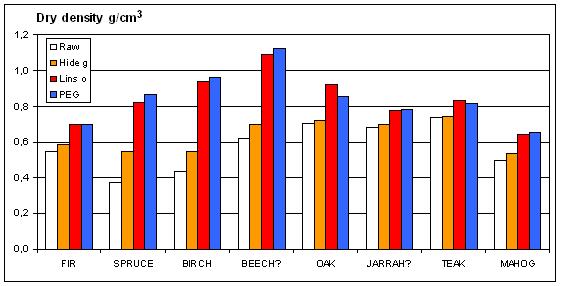

| 1 |

Fir |

Yellow |

0,543 | Soft |

Lumberyard |

| 2 |

Spruce |

White |

0,373 | Soft | Lumberyard |

| 3 |

Birch |

White | 0,437 | Med |

Bookshelf |

| 4 |

Beech? |

White | 0,618 | Hard |

Australian sun

chair |

| 5 |

Oak |

Brown |

0,706 | Hard | Chair |

| 6 |

Jarrah? |

Red |

0,676 | Hard | Kitchen workbench |

| 7 |

Teak |

Brown |

0,738 | Med | Chair |

| 8 |

Mahogany |

Red |

0,495 | Soft | Yacht carpentry |

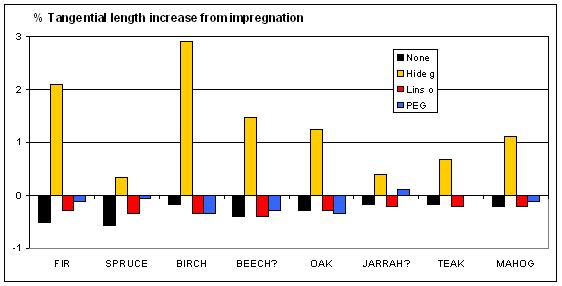

On

the flat side of each sample a diametrical shallow groove was filed

in the general direction of the year rings. This direction was hard to

determine

for species 4 and 8, possibly in error. The round shape makes it easy

to measure diameter separately along and across

the year rings, corresponding to the tangential and radial directions

in the growing stem.

On

the flat side of each sample a diametrical shallow groove was filed

in the general direction of the year rings. This direction was hard to

determine

for species 4 and 8, possibly in error. The round shape makes it easy

to measure diameter separately along and across

the year rings, corresponding to the tangential and radial directions

in the growing stem.| Design |

Treatment |

| A |

None, for reference |

| B |

Hot hide glue. Classical style.

Acqueous gel,

partially filling and sealing the pores. Its water content makes the

samples change dimensions at impregnation and surface smoothness is

degraded. The water

content of the impregnant will evaporate to leave void pore cavities

after drying. |

| C |

Boiled linseed oil. Seaman

style. The absence

of water may allow for better filling of the pores. The oil hardens

from oxidizing in the following days/weeks. (In contrast to raw linseed

oil which does not harden). |

| D |

Polyethene glycol, PEG 1500.

Conservator style. Water soluble (though no water was used), melting

point in the 40 C

range, white substance with a fatty surface, looking like wax or

stearine. |